ma-N 1400 - Negative Tone Photoresist Series

for Conventional Pattern Transfer and Single-Layer Lift-Off Processes

Unique Features

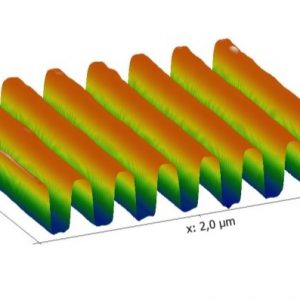

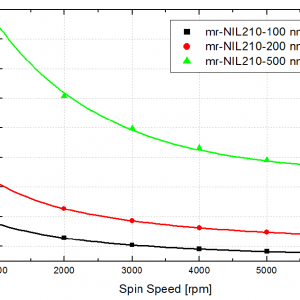

- Resists available in a variety of viscosities

- Aqueous alkaline development

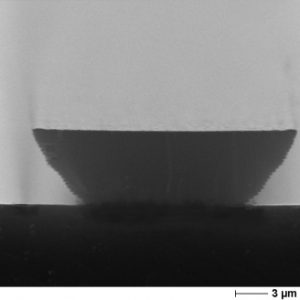

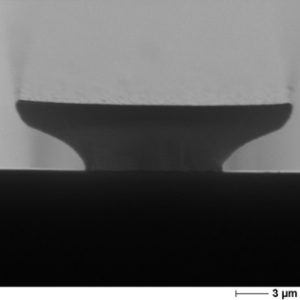

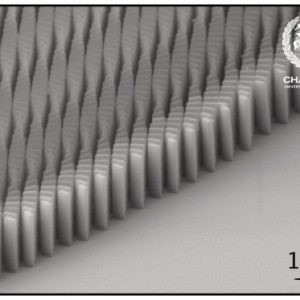

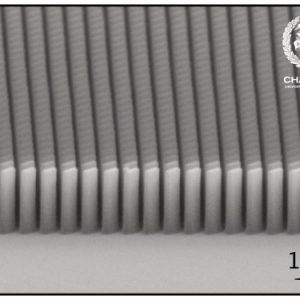

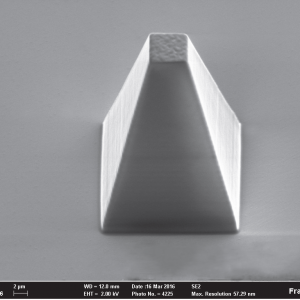

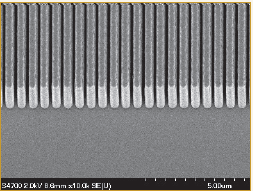

- Tunable pattern profile: vertical to undercut

- High wet and dry etch resistance

- Good thermal stability of the resist pattern

- Easy to remove

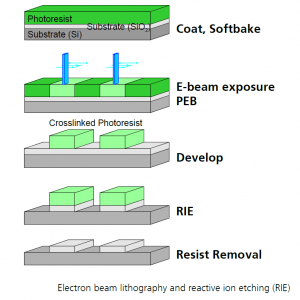

Applications

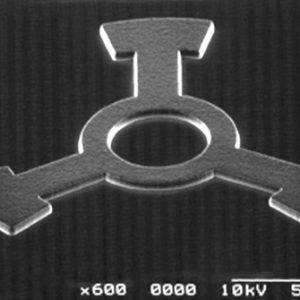

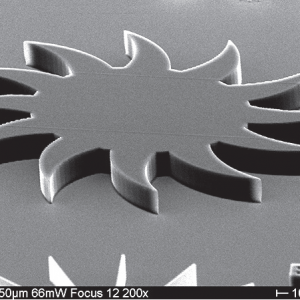

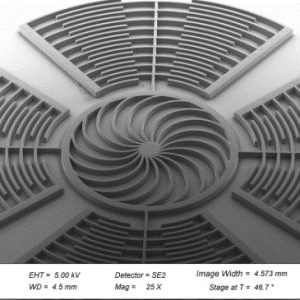

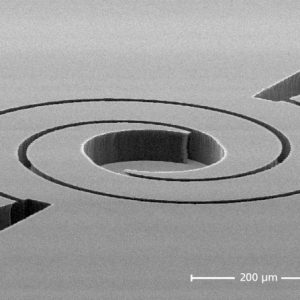

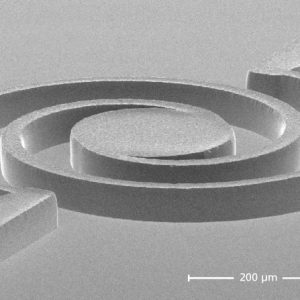

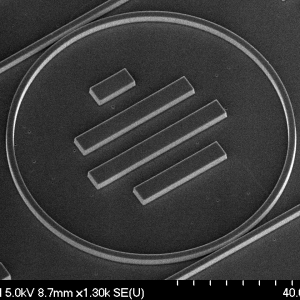

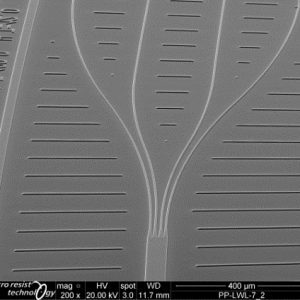

- Microelectronics and micro systems technology

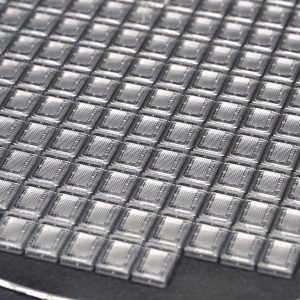

- Mask for lift-off processes

- Etch mask for semiconductors and metals

- Well suitable for implantation

- Mould for electroplating

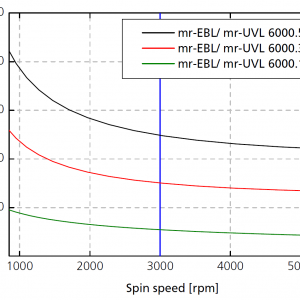

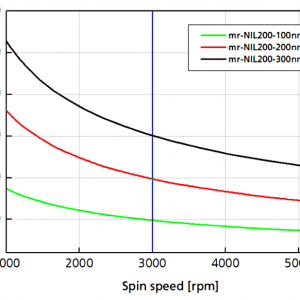

| Resist | Film Thickness [µm] spin coating @ 3000 rpm |

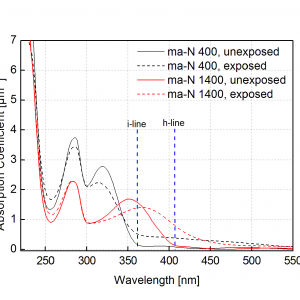

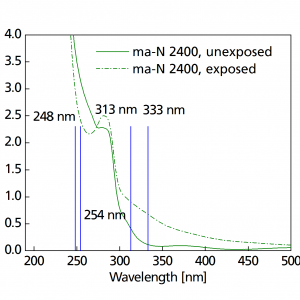

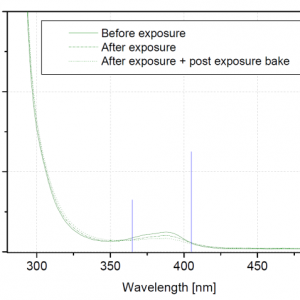

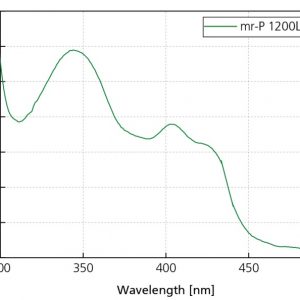

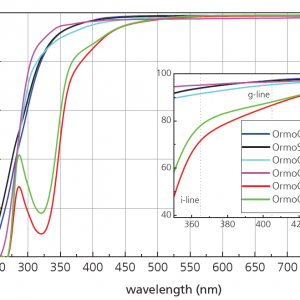

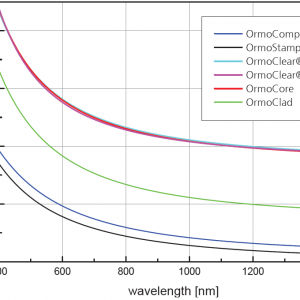

Spectral Sensitivity | Special Feature |

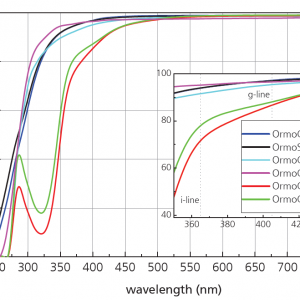

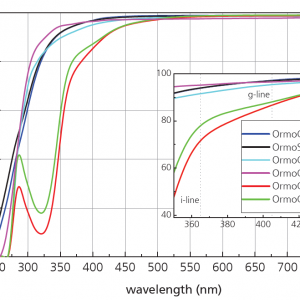

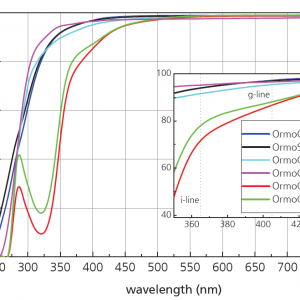

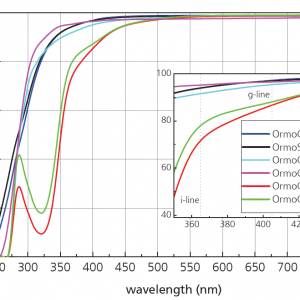

| ma-N 1405 | 0.5 | 300 - 410nm

i-line - 365 nm (h-line - 405 nm) |

Novolak based resist, thermal stability up to 160°C for metal evaporation and sputtering |

| ma-N 1407 | 0.7 | ||

| ma-N 1410 | 1.0 | ||

| ma-N 1420 | 2.0 | ||

| ma-N 1440 | 4.0 | ||

| ma-N 402 | 0.2 | 300 - 380nm

i-line - 365 nm |

Novolak based resist, thermal stability up to 110°C for metal evaporation |

| ma-N 405 | 0.5 | ||

| ma-N 415 | 1.5 | ||

| ma-N 420 | 2.0 | ||

| ma-N 440 | 4.1 | ||

| ma-N 490 | 7.5 |

Recommended process chemicals:

for ma-N 1400 Series

Thinner: ma-T 1046

Developer: ma-D 533/S (TMAH based)

Remover: mr-Rem 700 (NMP & NEP free), mr-Rem 500 (NMP free), ma-R 404/S (strongly alkaline)

Lift-off: mr-Rem 700 (NMP & NEP free), mr-Rem 500 (NMP free)

for ma-N 400 Series

Thinner: ma-T 1049

Developer: ma-D 331/S, ma-D 332/S (NaOH based), 531/S, ma-D 532/S (TMAH based)

Remover: mr-Rem 700 (NMP & NEP free), mr-Rem 500 (NMP free), ma-R 404/S (strongly alkaline)

Lift-off: mr-Rem 700 (NMP & NEP free), mr-Rem 500 (NMP free)